Vertical Hydraulic Press Rubber Molding Machine

JD-H Series

FEATURES

- This series of machines is suitable for molding many different plastic related materials. Such as rubber, melon dishes, bakelite, urea powder, foaming, brakes, etc.

- PLC and HMI functional control as standard specification.

- Integrated hydraulic circuit provides various pipe functions on the circuit boards, reduc- ing piping to a minimum. The oil cooler ensures long service life of the circuit valve.

- The motion time, and a number of other parameters can be conveniently set on the control panel to meet product variations, ensuring production quality.

- Combines two molding units in one machine, which can be operated separately. While in vulcanization molding operations, the hydraulic pump motor can be set for running, or stopped for power saving.

- The electric system is controlled by the PLC controller, allowing for easy operation and accurate adjustment.

- An emergency switch provides added safety for the mold and the operator.

INTRODUCTION

JD-H series vertical hydraulic press rubber molding machine is a specialized type of equipment designed to mold rubber components through the injection of rubber material into a mold cavity. It utilizes a hydraulic system to generate the necessary pressure for injecting the rubber material into the mold. The vertical configuration of the machine allows for easy accessibility and efficient operation.

SPECIFICATION

Factors to consider when choosing a vertical hydraulic press rubber molding machine include the clamping force, injection volume, shot size, and mold size compatibility:

| MODEL | JD-H50T | JD-H65T | JD-H80T | JD-H100T | JD-H150T | JD-H200T | JD-H300T | JD-H400T | JD-H700T | |

|---|---|---|---|---|---|---|---|---|---|---|

| Clamping Force | Ton | 50 | 65 | 80 | 100 | 150 | 200 | 300 | 400 | 700 |

| Plate Size | mm | 350 x 380 | 350 x 380 | 430 x 490 | 500 x 560 | 510 x 510 | 600 x 620 | 730 x 730 | 900 x 900 | 1200 x 1200 |

| Piston Diameter | mm | 180 | 200 | 230 | 270 | 310 | 355 | 430 | 500 | 660 |

| Piston Stroke | mm | 380 | 380 | 380 | 380 | 320 / 420 | 480 | 360 / 600 | 360 / 630 | 760 |

| Space Between Tie Bar | mm | 395 x 220 | 430 x 200 | 475 x 300 | 575 x 345 | 550 x 300 | 675 x 365 | 795 x 455 | 970 x 580 | 1360 x 800 |

| Daylight Max | mm | 500 | 500 | 500 | 550 | 550 | 650 | 700 | 750 | 1000 |

| Oil Hydraulic System | HP | 5 | 5 | 5 | 7.5 | 7.5 | 10 | 15 | 20 | 25 |

| Platen Heating Capacity | kw | 4.8 | 4.8 | 7.4 | 9.8 | 9.2 | 14.8 | 21 | 35.2 | 76 |

| System Pressure | kg / cm² | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 |

| Oil Tank Capacity | liters | 250 | 250 | 250 | 350 | 350 | 430 | 470 | 560 | 700 |

| Machine Dimensions | mm | 1485 x 1955 x 1970 | 1485 x 2005 x 1970 | 1485 x 2065 x 1970 | 1585 x 2175 x 2020 | 1585 x 2185 x 2270 | 1635 x 2325 x 2370 | 1745 x 2455 x 2520 | 1885 x 2685 x 3020 | 2285 x 3355 x 3670 |

| Machine Weight (Approx) | kg | 2400 | 2600 | 2800 | 3600 | 3700 | 5100 | 6300 | 11000 | 17600 |

|

*Dimensions are as standard, subject to change by options or upon custom-made;actual specifications are based on the finished products. *表內為標配尺寸,會因選配或客製化而有所差異,請以實際為準 |

||||||||||

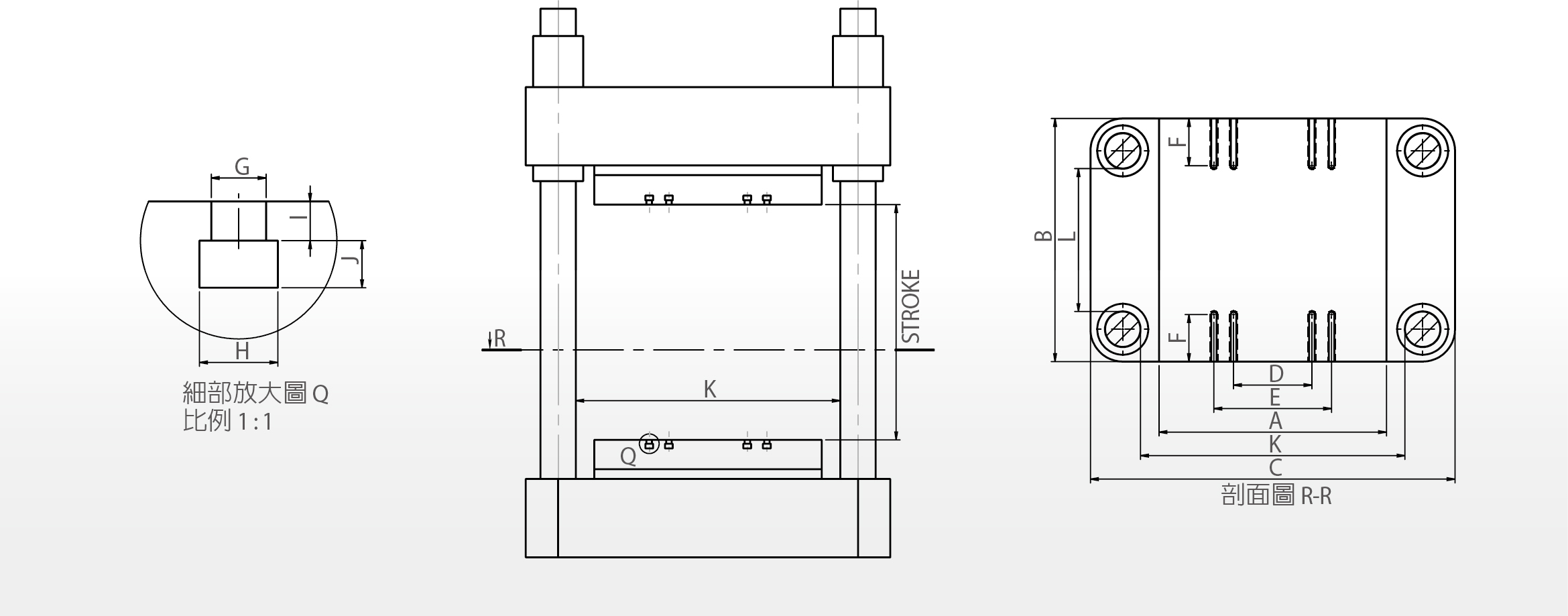

MOLD INSTALLATION & HEATING PLATE DIMENSION

| MODEL | JD-H50T | JD-H65T | JD-H80T | JD-H100T | JD-H150T | JD-H200T | JD-H300T | JD-H400T | JD-H700T |

|---|---|---|---|---|---|---|---|---|---|

| STROKE / DIMENSION | 380 | 380 | 380 | 380 | 320 / 420 | 480 | 360 / 600 | 360 / 630 | 760 |

| A (mm) | 350 | 350 | 430 | 550 | 510 | 600 | 730 | 900 | 1200 |

| B (mm) | 380 | 380 | 490 | 560 | 510 | 620 | 730 | 900 | 1200 |

| C (mm) | 560 | 610 | 670 | 780 | 780 | 930 | 1060 | 1290 | 1760 |

| D (mm) | - | - | - | 200 | 200 | 200 | 300 | 300 | 500 |

| E (mm) | 200 | 200 | 200 | 300 | 300 | 400 | 500 | 700 | 1000 |

| F (mm) | 135 | 135 | 135 | 135 | 135 | 200 | 200 | 250 | 350 |

| G (mm) | 14 | 14 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| H (mm) | 20 | 20 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| I (mm) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| J (mm) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| K (mm) | 395 | 430 | 475 | 575 | 550 | 675 | 795 | 970 | 1360 |

| L (mm) | 220 | 200 | 300 | 345 | 300 | 365 | 455 | 580 | 800 |

It is important to select a vertical hydraulic press rubber molding machine with sufficient clamping force to accommodate the size and complexity of the molds. The injection volume and shot size should align with the required material quantity for each part. Additionally, ensuring that the machine can accommodate the desired mold size is crucial for producing the desired products. If you have any needs or questions, welcome to contact us!